Insight

DC-ENERGY supplies machines, plants, machine components, tools and services in the entire process chain of battery production:

From raw material preparation, electrode production and cell assembly to module and pack production.

Battery manufacturing process for LiB

We offer all equipment for Lithium Ion Battery manufacturing

Processes

Electrode manufacturing: Mixing

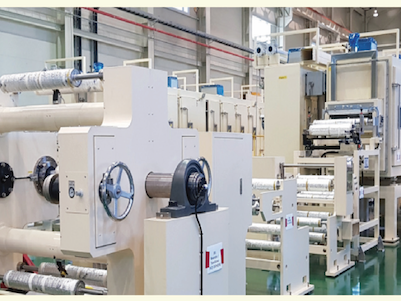

Electrode manufacturing: Coating

Cell assembly: Separation

Formation: Cell finishing